The automotive industry is undergoing a period of unprecedented transformation. Electrification, autonomous driving, and software-defined vehicle technologies are reshaping the landscape, placing a premium on innovation and efficiency. Artificial intelligence (AI) and especially generative AI (GenAI) has emerged as a powerful tool for car manufacturers and suppliers, offering significant economic benefits and streamlining product development processes. This article explores the transformative impact of AI on automotive product development, introducing our comprehensive use case model and a practical approach to identifying and implementing the most valuable applications for your business.

Significant economic impact of GenAI on automotive product development

A recent McKinsey report called “The economic potential of generative AI - The next productivity frontier” tried to quantify the impact of GenAI across 63 use cases. I don’t want to go deeper into the “$2.6 to 4.4 trillion” that GenAI could add to the global economy. But I do like the finding that 75% of the value comes from use cases in the four areas of Customer Operations, Marketing & Sales, Software Engineering and Product R&D.

McKinsey attributes the economic impact mainly to the potential of automating more than 50% of knowledge worker’s tasks. I would add the impact on time-to-market and on innovation: improved requirements and test cases as a rather mature GenAI use case can limit the number of changes, thus speeding up the development. This not only frees up capacity for innovation, AI can also support the generation and evaluation of new design ideas.

AI enables Data-Driven Engineering

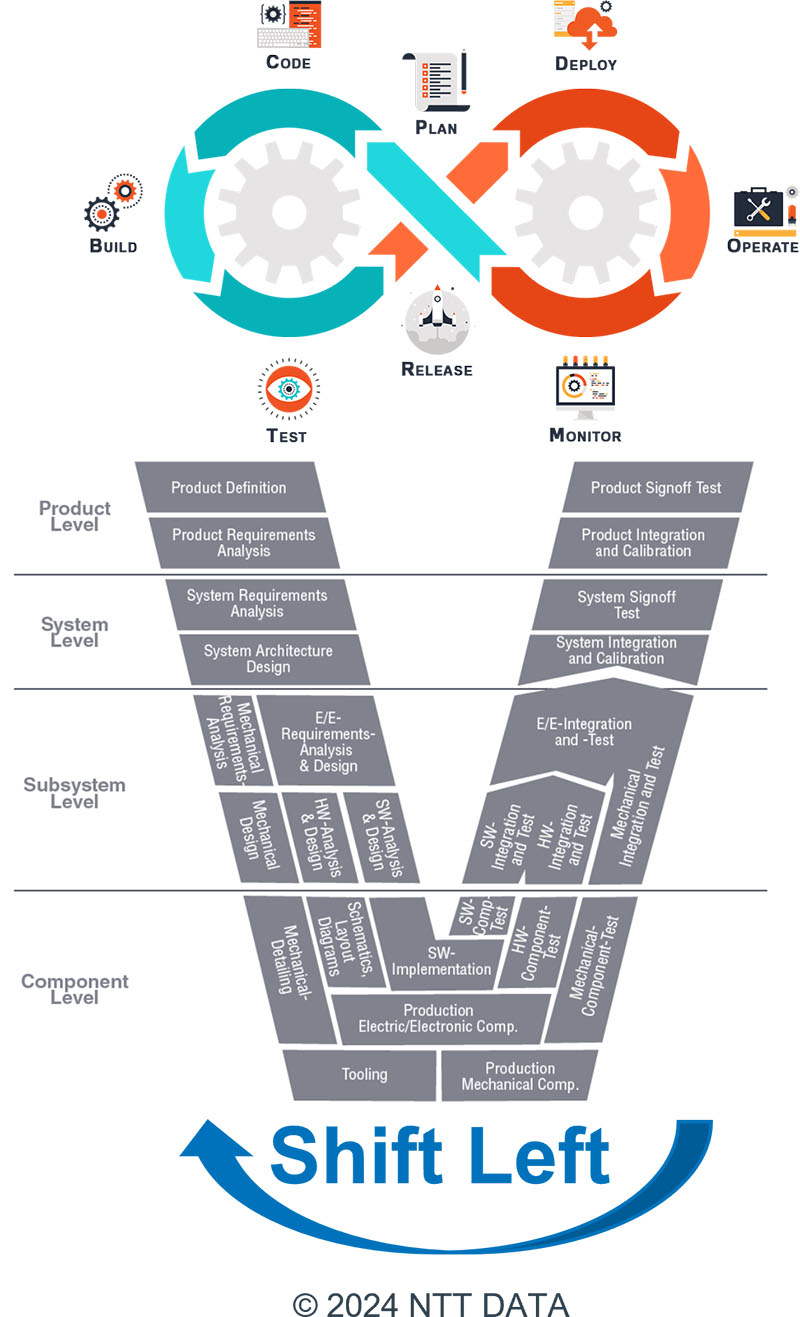

Automotive is a data-rich industry: connected cars and smart factories produce immense amounts of data. Data-driven engineering is about use cases for this data in product development. At NTT DATA, we have developed a comprehensive model of 25+ AI use cases for product development, organized along the systems engineering V model and the phases of the product lifecycle. We describe each use case in terms of business functionality, required data and technological approach, for example GenAI, machine learning, natural language processing etc.

As an example, let’s take the use case of Patent Management. GenAI can support various processes such as patent search, classification, patent landscape analysis, summarization, drafting assistance and translation. This requires access to internal and external patent information. The technological approach would include large language models, natural language processing methods such as concept mapping, topic modeling and semantic search.

Value-Based Assessment of Use Cases

With limited resources and time, it is essential to identify and implement the high-value use cases for your organization. Our use case model uses three criteria for a first approach:

- Efficiency potential: The impact on efficiency within the automotive product development process. Considers factors such as time savings, cost reduction, resource optimization, and overall productivity improvements.

- Feasibility: Examines whether a use case is practical and achievable within the current technological and organizational constraints. Factors to consider include data availability, technology readiness, regulatory compliance, and integration challenges.

- Effort: evaluates the level of resources, including time, expertise, and investment, required to implement and maintain the use case successfully.

This kind of assessment allows us to concentrate on the upper-right corner, which represents use cases with high feasibility and significant efficiency potential. Examples in this quadrant include GenAI-based support for requirements engineering, as well as related test plans and test cases. Additionally, we find the well-established field of software development assistants, exemplified by Microsoft’s GitHub Copilot.

Conclusion

The digital transformation of the automotive industry is ongoing, and AI is a key tool for competitive advantage. NTT DATA is dedicated to collaborating with clients on this journey, providing expertise and support to navigate the opportunities presented by AI in automotive product development.

As a first step, we suggest our Proof-of-Value offering, which provides a hands-on experience with your priority use cases using your data within a pre-configured cloud environment. Feel free to contact us for further details on our AI solutions for engineering.

Note: this is a cross-post from the article on the NTT DATA website under GenAI in Motion - Redefining the Automotive Product Development Landscape | NTT DATA Group